how to measure subfloor thickness|subfloor thickness chart : Chinese The thickness and stiffness of the subfloor will determine the types of finish materials that can be used. Key Points: Fasten the first row of joists completely before moving . Resultado da 1 de nov. de 2023 · Fapello brings something new to the video-sharing industry. This article will examine What is Fapello?, Is Fapello Safe, .

{plog:ftitle_list}

17 de dez. de 2018 · Ou, com certeza, você já deve ter ouvido algum comentário do tipo “achei que aquela atriz fosse mais alta”. Já que as imagens muitas vezes enganam, nós esclarecemos para você qual é a .

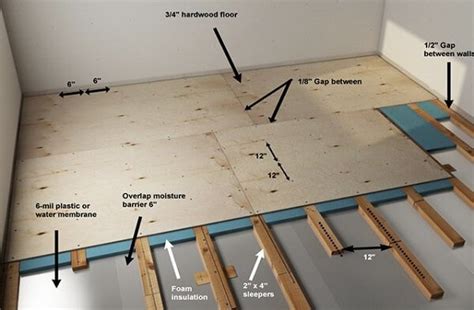

The typical subfloor thickness should be at least 3/4 inches. Plywood or OSB (Oriented Strand Board) are common materials used. Ensuring the right subfloor thickness is essential for a stable and long-lasting flooring .

Subflooring only adds 3/4 inch to the floor thickness. There are two main types of subflooring, plywood and oriented strand board, or OSB. Both come in 4-by-8 sheets and feature tongue-and-groove installation. Construction . Introduction. Beneath those nice wood planks, cozy shag carpet, or sleek ceramic tile lies an essential supportive layer known as the subfloor. Subfloors form a base platform mounted directly over the lowest level floor .

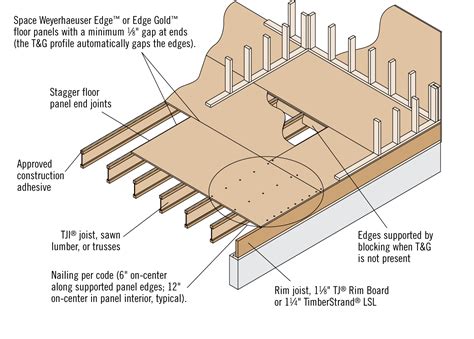

The thickness and stiffness of the subfloor will determine the types of finish materials that can be used. Key Points: Fasten the first row of joists completely before moving . Generally, the minimum thickness for plywood is 5/8 inch; for OSB it's 23/32 inch. However, as joist spacing increases, the subfloors need to be thicker. For joist spacing of more than 16 inches up to 19.2 inches on .

Your plywood subfloor should be ⅝ or 23/32 inch thick. It’s the ideal thickness for every plywood subfloor since you will use it as the best-protected layer on your tile floor. You may find different plywood thicknesses, but they will not give you . Calculating Deflection. Many tile contractors can judge a floor’s deflection by walking around. To calculate a specific value, the Tile Council of North America (TCNA) offers a standard formula. The thickness of the plywood directly impacts the strength and stability of your floor. In this guide, we will explore the optimal plywood thickness for different types of subfloors, factors to consider when selecting the right .To prepare your concrete subfloor, make sure that it can accept water penetration. Test by sprinkling water on various areas of the subfloor. If water penetrates and leaves a wet spot, then a good bond can be achieved.

Measure and cut the subfloor panels to fit the dimensions of the bathroom. Start by laying the panels along the perimeter of the room, leaving a small gap between each panel to allow for expansion. Secure the panels to the existing floor .

3) Check Before Installation: Once you determine the subfloor is the proper thickness, check that the subfloor is installed properly, with no issues that could affect your installation. Subfloor panels and fasteners should be .Measure the length, width, and thickness of the old threshold, and have a replacement with a similar profile on hand. It should be an inch or two longer than the distance between the door casing’s outside edges so you can trim it for an . The subfloor is the decking installed on top of flooring joists and then the finished floor—like carpet, plank vinyl, or tiles—is then installed on top. The minimum plywood thickness for a subfloor is determined by the spacing of the joists. This number is known as a span rating.

The subfloor is the layer of structural sheathing applied directly to the joists that provides a base for all the finish floors to come. Some types of flooring, such as carpet or traditional hardwood, can be installed directly on top of the subfloor.

Measure Your Subfloor Thickness. Next, you will need to measure your subfloor. Most subfloors are either 3/4″ or 5/8″ thick. You will use the measurement to set your circular saw to the proper height. One of the most tedious parts of replacing subflooring in mobile homes is the removal of the original sub-flooring. Measure the height of the rough opening by looking at the bottom corners where the interior door casing used to be and locate the subfloor. The subfloor is the solid material that extends underneath your door unit and floor covering. Measure from the subfloor to the top of the rough opening on each side. Write down the smallest of these dimensions. Here are some ideas for how to measure the thickness of your floor covering and/or subfloor. You will require a tape measure or a ruler with a straight edge. Floor heating vent: The best way to determine the total floor thickness is to remove an HVAC vent from the floor. It is very simple to remove floor vents that are part of your central . Using a tape measure, measure from one end to another and ensure that all joists are spaced evenly apart. This will help you create an even subfloor surface when laid down later. 3. Number of Subfloor Sheets: The number of plywood sheets you will need to install your subfloor depends on the size of your space, and how much coverage you require.

Minimum Layers Of Plywood For Subfloor: 1 Layer At 3/4″ Thickness. The number of layers of plywood for a subfloor should be determined based on the minimum requirement. According to industry standards, a subfloor should have at least one layer of plywood with a thickness of 3/4″. This thickness ensures a sturdy base for the flooring . How to lay a plywood subfloor. A subfloor will provide a smooth, level surface upon which to lay a floor covering. The type of wood board you use will depend on what the existing floor is made from and the type of floor covering you want to lay. The most common form of wooden subfloor is plywood. What is the Actual Thickness of a Sheet of Plywood. Plywood is often sold in 1 / 4 “, 1 / 2 “, or 3 / 4 ” nominal thicknesses, but the actual thickness is often 1 / 32 ” thinner. Because the actual thickness may vary, measuring the plywood sheet using a caliper is the only accurate way to determine its thickness. A 3 / 4 ” sheet is .

hydraulic test gauge set

The spacing of the joists governs the recommended thickness of the plywood subfloor. Some experts suggest that 15/32-inch plywood should be standard if the underlying floor joists are spaced 16 inches apart or less, but you should use slightly thicker 3/4-inch plywood for joists spaced further apart. However, check with your local code .Measure scrap pan liner for curb. Tip: Oatey pan liners are marked in 6 in. increments for easy measuring. For overall curb width, measure the inside and outside heights of the curb, as well as the top width of the curb, and add them together. Measure the length of the curb, then cut a piece of the liner off to those measurements. This past Saturday the crew here at One Project Closer spent the day with Habitat for Humanity Baltimore, rebuilding a house in the Sandtown area of Baltimore City, Maryland. We shared the day with a dozen volunteers, .Insulation levels are specified by R-Value. R-Value is a measure of insulation’s ability to resist heat traveling through it. The higher the R-Value the better the thermal performance of the insulation. The table below shows what levels of .

For optimal support, ensure that the plywood subfloor has a thickness of at least 3/4 inch (19mm). For example, if you are using a plywood subfloor in a living room, you can install 12mm laminate flooring over a 3/4 .3. Measure the Gap You Need to Fill. In almost every scenario, the gap you’ll need to fill with a subfloor will be between a stair landing and the floor above or below it. This means you’ll have to alter the height of your subfloor in the range of 1/4” to 1”, and you’ll almost never need to raise a subfloor a whole inch at a time. ½” is the most common plywood thickness for subfloor installations; . The hosts explain the step-by-step process of replacing the subfloor, including measuring the area, adding support boards, ensuring level floor joists, gluing the plywood, and securing it with screws. The importance of leaving gaps between plywood sheets is also emphasized.

CincinnatiHouseBuyer, any licensed structural engineer will be able to determine what changes need to be made to go with OVE. Building codes and manufacturer specs usually list options for 24" o.c. framing, but you may need an engineer or architect to sign off on some of the other changes, such as a single top plate, and to specify appropriate fasteners and hold-downs. Subfloor sheathing provides stability and a stiff surface for a finished floor. . In general, the minimum thickness for standard subflooring is 3/4 in., which can handle a load of 100 lb. per sq. ft. at 16-in. joist spacing. However, you can also use 15/32-in. or 1/2-in. subflooring to span 16-in. on-center joist spacing. . This video covers measuring, cutting, and the correct tricks for installing, to ensure a good bond and long-lasting results that never squeak! For links to p.

Floor heating vent: Remove a floor HVAC vent by lifting it straight up.With the vent removed, you have a wide, clear view of a cross-section of your floor. Top of stairs: Sometimes, the top of a staircase has an unfinished opening that permits a cross-section view of the entire floor. Even if the stairs are fully finished, you can get an approximate thickness reading by . Considering spacing my floor trusses at 24″ oc. Trusses are 3.5″ wide, so effective span of subfloor is 20.5″. Is 1″ subfloor the recommended thickness. Also, should I plan on [.] Floor thickness is a significant factor in the safety of engineering structures. Determining floor thickness is one of the critical items in engineering quality. So, how to measure the floor thickness? How to measure floor thickness. 1) Steel tape detection: open a hole in the floor or use the reserved hole on the floor for detection. Measure the thickness of the subfloor to determine the appropriate replacement thickness. Remove flooring materials, like carpet or vinyl, to expose the subfloor. Use a circular saw to create a clean edge along the perimeter of the damaged area. Cut along joists or support beams when removing the damaged section of the subfloor.

For joist spans 16 inches or less, NWFA recommends minimum panel thickness of 5⁄8-inch plywood or 23⁄32-inch OSB; the building code requires 5⁄8-inch plywood or OSB. When NWFA Guidelines minimums are not met, the recommendations are to overlay the existing subfloor material with a 1⁄2-inch panel product or add structural support from below.

what thickness plywood for subfloor

Resultado da 27 de out. de 2023 · Nine terrifying stories from the pens of the new Latin American masters of horror, based on the mythic 80s series. MIAMI – OCT. 27, 2023 – ViX, the leading Spanish-language streaming service in the world, announced today that LA HORA MARCADA (The Marked Hour), the new .

how to measure subfloor thickness|subfloor thickness chart